In order to more comprehensively analyze the problem of surface roughness of EPDM extruded products, it becomes essential to combine the data analysis with the measurement parameters in actual production. This data is not only the key to accurately locating problems, but also provides the basis for quantitative evaluation and effectiveness monitoring when implementing improvement measures. Next, we will detail the data analysis methods and corresponding measurement indicators in several key areas. Best sealing rubber silicone material

1、raw material quality assessment

1. Material fluidity analysis

The fluidity of EPDM material is an important factor affecting its extrusion effect. As measured by the Mooney viscosity test (ML1+4, 100°C), the ideal viscosity range is usually between 50-70. High viscosity can lead to poor material flow during extrusion, resulting in uneven surfaces.

Improvement measures: Adjust the ratio of plasticizer or filler to optimize the fluidity.

Monitoring means: Periodic test of Mooney viscosity to ensure batch stability of materials.

2. Evaluation of material dispersion

The uniform distribution of the filler or plasticizer in the material is critical to the surface quality of the product. Using scanning electron microscopy (SEM) and particle size analyzer, the particle size distribution and uniformity of the filler can be evaluated.

Objective: The particle size of the filler is controlled at 0.5-1 microns, and the distribution is uniform.

Evaluation methods: Different batches of SEM images were compared to evaluate the dispersion effect.

2、Optimization of extrusion process parameters

1. Monitor temperature distribution

The extrusion temperature is usually set between 100-110°C, and temperature uniformity is crucial to the surface quality of the product.

Monitoring tools: thermocouples and temperature sensors.

Optimization strategy: Adjust the heating section Settings according to the temperature data, such as appropriate cooling at the front of the cooling section.

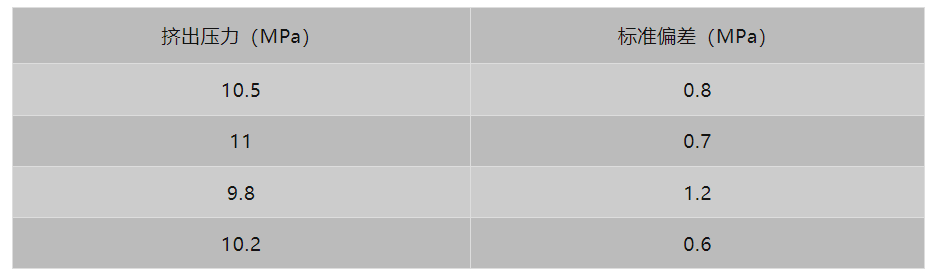

2. Extrusion pressure management

Pressure stability affects the flow uniformity of the material, which in turn affects the surface quality.

Ideal range: 8-12 MPa.

Evaluation index: Standard deviation of pressure fluctuation, smaller indicates more stable.

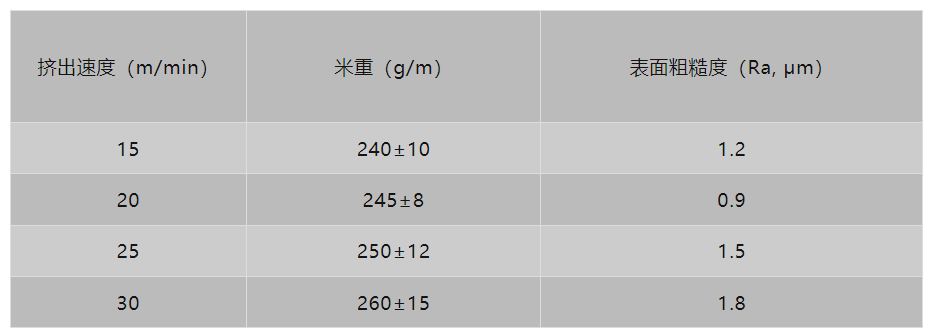

3. Extrusion speed and cooling effect

The extrusion speed needs to match the cooling effect and is evaluated by meter weight and surface roughness data.

Recommended range: extrusion speed 15-30 m/min, meter weight standard deviation is small, roughness value (Ra) is low.

3、equipment maintenance and monitoring

1. Screw torque monitoring

The torque of screw is an important index to evaluate the health state of equipment.

Normal/wear/maintenance threshold: 450 Nm/470 Nm/510 Nm (>500 Nm when maintenance is required)

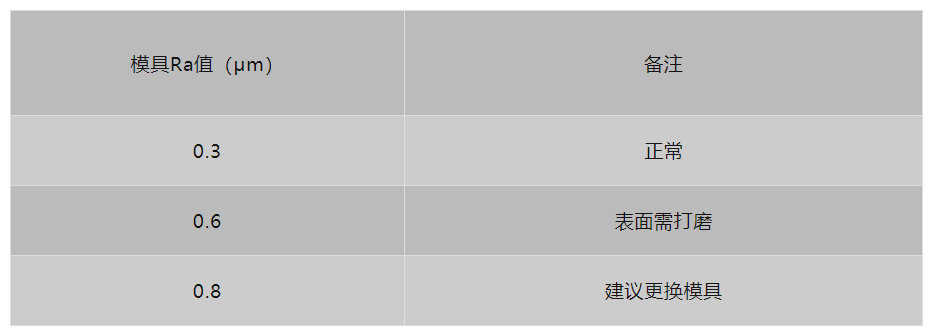

2. Mold surface roughness

The surface roughness of the die directly affects the surface quality of the product.

Recommended range: Ra value 0.2-0.5 μm.

Maintenance standard: Ra> 0.6μm need to be polished, > 0.8μm recommended replacement.

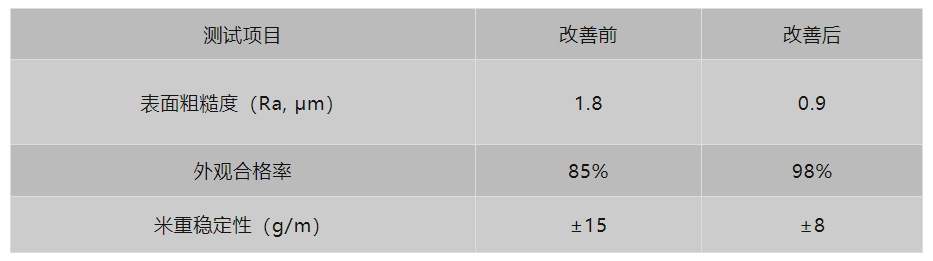

4、improve the effect evaluation

1. Surface roughness and appearance detection

The improvement was evaluated by roughness meter and high precision camera equipment.

Target: Ra value < 1.0μm, improve the appearance pass rate.

2. Data comparison

Before and after improvement: surface roughness decreased from 1.8μm to 0.9μm, appearance pass rate increased from 85% to 98%, meter-weight stability improved.

conclusion

Data analysis plays a central role in optimizing the surface quality of EPDM extrusions. Through comprehensive monitoring of raw material quality, extrusion process parameters, equipment maintenance and cooling systems, problems can be precisely located and targeted improvements implemented. Data management not only improves product quality, but also promotes the formation of continuous improvement mechanisms, improving production efficiency and quality standards.

Special statement: The content source is for reference only, in order to convey more information and not profit. Copyright belongs to the original author. If there is infringement, please contact delete.