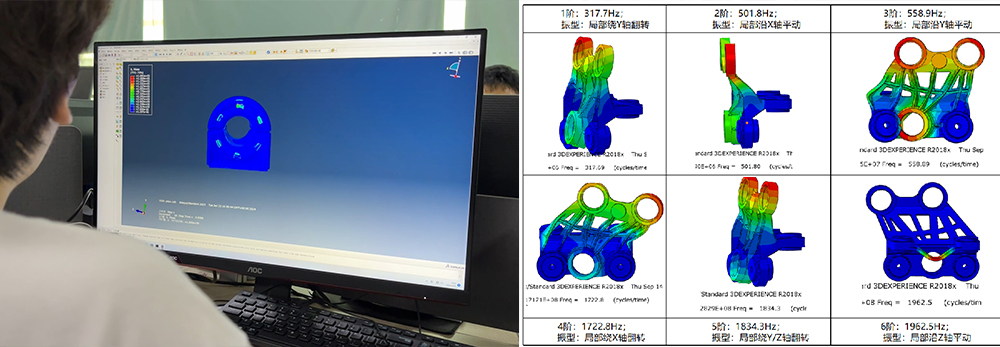

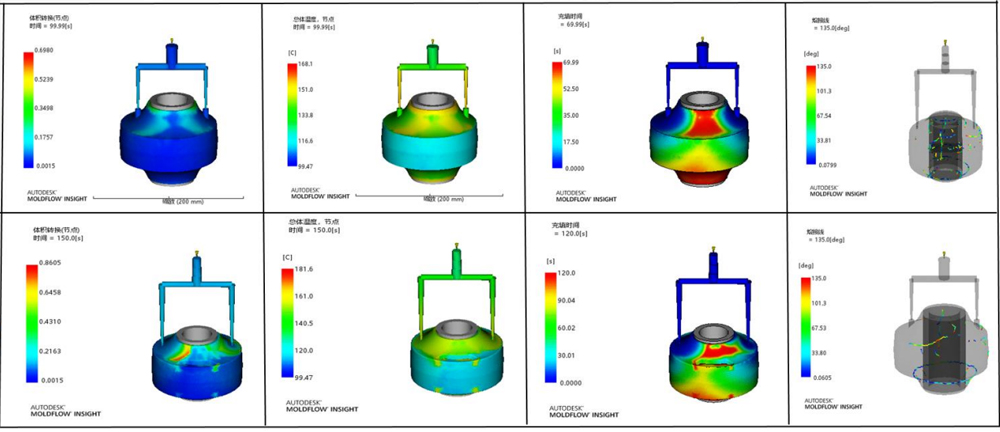

CAE Simulation Design

In the modern rubber manufacturing industry, Computer-Aided Engineering (CAE) simulation design is an essential tool for improving product performance, shortening development cycles, and reducing production costs. We have a specialized CAE simulation design team dedicated to providing efficient and precise R&D support for our customers.

Through accurate simulation modeling, we can predict product performance in various working environments, ensuring the rationality and effectiveness of the design. Additionally, by simulating the characteristics of rubber materials, we can optimize formulations and material selections to ensure that the final products exhibit the best performance. This not only enhances product quality but also increases reliability in practical applications.

During the product design phase, we employ CAE technology for virtual testing to evaluate the strength, stiffness, and fatigue life of designs. Through repeated simulation validation and optimization, we ensure that every product reaches its optimal state before production, thereby reducing the costs associated with later modifications.

By integrating CAE simulation design technology, we continuously drive product innovation and enhancement, ensuring that we provide high-performance and high-quality rubber solutions for our customers.

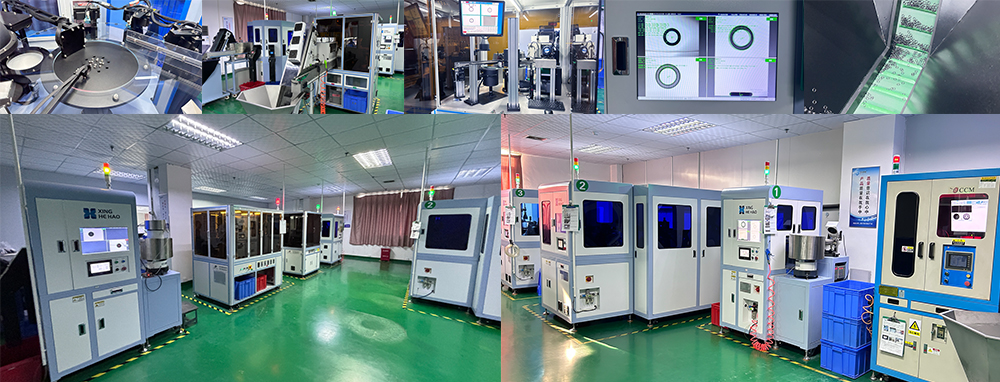

Automatic Loading and Unloading Machine

In modern rubber manufacturing processes, the automatic loading and unloading integrated machine serves as an advanced automation device designed to enhance production efficiency, reduce labor costs, and ensure product quality. This equipment integrates automatic loading and unloading functions, providing a one-stop solution for rubber production lines.

By utilizing an automated system, the machine achieves rapid loading and unloading, reducing reliance on manual labor. This not only lowers labor costs but also improves production efficiency, ensuring continuity in the production process and significantly shortening production cycles. Additionally, the machine can be flexibly adjusted to accommodate different production requirements, making it suitable for various sizes and weights of rubber products to meet diverse production needs.

CCD Automatic Full Inspection Machine

In the rubber industry, the stability and consistency of product quality are crucial. Our automatic inspection machine is an advanced piece of equipment introduced to ensure product quality. This device conducts comprehensive inspections of multiple key indicators, such as product appearance and dimensions, ensuring that each parameter meets design requirements and thereby improving overall product quality.

The built-in projector quickly captures product parameters, enabling the fast and efficient identification of non-conforming products while minimizing human error. This significantly reduces the occurrence of defective products, ensuring that every item delivered to customers meets quality standards, thus enhancing customer satisfaction and trust.

The automatic inspection machine is an essential tool in our product quality management, dedicated to providing safer and more reliable rubber products for our clients and promoting the sustainable development of our enterprise.