Protective wax, as an indispensable additive to rubber products, its core function is to prevent the aging of rubber in the process of use. Its mechanism of action is complex and diverse, including building physical barrier, trapping ozone molecules, delaying chemical reaction process and so on. The purpose of this paper is to discuss the mechanism, advantages and disadvantages of protective wax, as well as its future development trend.

1. Protective wax mechanism

Under continuous exposure to the external environment, rubber materials will be eroded by multiple factors such as oxygen, ozone, ultraviolet light and temperature changes, resulting in aging. Protective wax effectively slows the aging rate of rubber through the following mechanisms:

1.1 Physical protective barriers

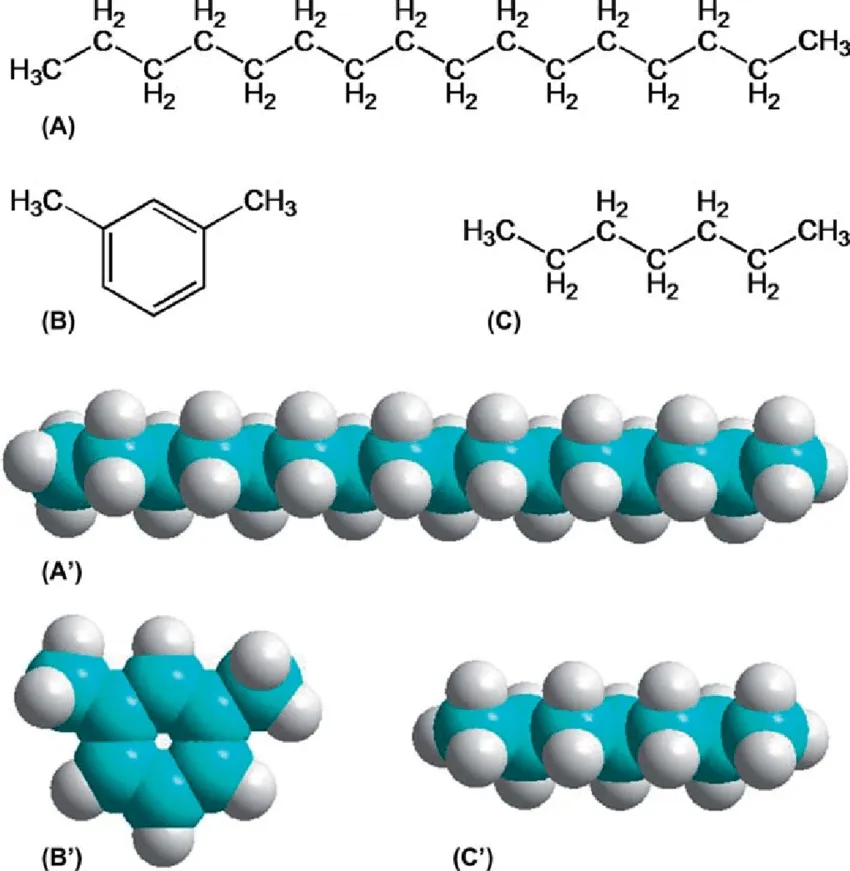

One of the main functions of the protective wax is to form a protective film on the rubber surface, which can effectively block the direct contact between external harmful substances (such as oxygen, ozone, ultraviolet, etc.) and the rubber matrix. When the rubber is in the atmosphere, the protective wax will migrate from the inside of the rubber to the surface, and gradually form a layer of dense wax barrier. This barrier significantly slows the penetration rate of harmful substances and reduces direct damage to rubber molecules.

1.2 Ozone capture and isolation

The protective wax, through the non-polar part of its chemical structure, is able to adsorb and capture ozone molecules in the air, thereby preventing the reaction of ozone with the unsaturated bonds in the rubber and avoiding the break of the rubber molecular chain. This process mainly relies on the adsorption capacity and physical barrier properties of the protective wax, which effectively reduces the ozone aging of the rubber and prevents the generation of surface cracks.

1.3 Thermal stability and oxidation resistance

The chemical properties of the protective wax give it a certain thermal stability, which can maintain a stable molecular structure within a certain temperature range and prevent the oxidation and decomposition of rubber materials at high temperatures. In a high temperature environment, the protective wax can also inhibit the oxidation chain reaction inside the rubber, and further delay the thermal oxygen aging. In addition, some protective waxes contain antioxidant components, which improve the anti-aging ability of rubber by blocking the generation of free radicals.

1.4 Adjust rubber surface properties

The film formed by the protective wax on the rubber surface can change the surface properties of the rubber and reduce its interaction with the outside world, thus weakening the influence of aging factors. This adjustment of surface properties not only reduces the erosion of ozone and oxygen, but also reduces the friction coefficient of the rubber surface, preventing the formation and expansion of tiny cracks.

2. Advantages of protective wax

2.1 Improve rubber durability

By building a physical barrier, the protective wax effectively delays the erosion of rubber by external factors and significantly improves the durability of rubber products. This makes the rubber material maintain the original mechanical properties and chemical stability for a long time, and extends the service life of rubber products.

2.2 Cost-effective and easy to add

Compared with other anti-aging additives, protective wax is low in cost and easy to add in the production process of rubber products. Its molecular structure is relatively simple, the production process is mature, and the production cost is low, which makes the protective wax widely used in the rubber industry.

2.3 Wide range of applications

Protective wax is suitable for a variety of rubber products, whether natural rubber or synthetic rubber, you can improve its anti-aging properties by adding protective wax. This feature makes protective wax a key additive in a variety of products such as tires, industrial rubber products, and automotive parts.

2.4 Stable chemical properties

Protective wax exhibits good chemical stability under usual storage and use conditions and does not react adversely with rubber or other additives. This stability ensures its effectiveness in the production and use of rubber products.

3. Disadvantages of protective wax

3.1 The protection effect weakens with time

Although protective wax can effectively prevent rubber aging in the short term, its protective effect may gradually weaken after long-term use. The migration rate of protective wax is not uniform, resulting in uneven protective effect. When the wax film is physically damaged or worn, the rubber surface loses protection and the aging speed is accelerated.

3.2 Limited thermal stability

Although the protective wax has certain thermal stability, under extreme high temperature conditions, some protective wax may lose its protective effect. In particular, wax materials with low melting point are easy to melt and lose in high temperature environments, resulting in exposure of rubber materials to harmful environments.

3.3 Limited UV protection effect

The protective wax is mainly isolated by the physical barrier effect of ozone, oxygen and other external factors, but the shielding effect of ultraviolet light is relatively weak. Although UV absorbers or stabilizers can be added to enhance protection, they are not as effective as specialized anti-UV additives.

3.4 Prevent wax migration

The distribution of protective wax in rubber products may be uneven, especially in the process of long-term storage or use, the protective wax will slowly migrate from the inside to the surface, resulting in the gradual weakening of the protective effect inside the rubber material. Protective wax that migrates to the surface may affect the appearance or other properties of rubber products.

4. The future development direction of protective wax

4.1 Research and development of environment-friendly protective wax

With the increase of global environmental awareness, the demand for environmentally friendly additives in the rubber industry is growing. In the future, the research and development of protective wax will pay more attention to the development of environmentally friendly wax materials, such as bio-based wax, degradable wax and harmless protective wax. This not only meets the requirements of environmental protection, but also reduces the environmental impact of rubber products after waste.

4.2 Innovation of multi-functional compound protective wax

Protective waxes with a single component have limited effectiveness in complex environments. In the future, the protective wax will develop into a multi-functional composite material, which can enhance its comprehensive protective effect by combining with other anti-aging agents, antioxidants or ultraviolet absorbers. This composite protective wax provides comprehensive protection for rubber under a variety of environmental conditions.

4.3 Exploration of intelligent protective wax

The research of intelligent materials has attracted much attention. The future protective wax material is expected to use intelligent technology to realize the function of adaptive adjustment of the protective effect according to changes in the external environment. For example, intelligent protective wax can automatically adjust its physical structure or chemical properties in response to changes in temperature, humidity or UV intensity, providing a more durable and stable protective effect.

4.4 Application of nanotechnology in protective wax

The application of nanotechnology has revolutionized materials science. In the research and development of protective wax, nanomaterials can improve its weather resistance, thermal stability and UV resistance by optimizing the molecular structure of protective wax. Nanometer wax film can significantly improve the protection effect and enhance the protection performance of rubber.

Special statement: The content source is for reference only, in order to convey more information and not profit. Copyright belongs to the original author. If there is infringement, please contact delete.