With the acceleration of global automotive electrification and intelligence, the "nervous system" of wiring harnesses is undergoing a restructuring. In 2025, China's new energy vehicle sales reached 12.86 million units (+35.5%), triggering an explosion in the wiring harness industry. In 2026, the focus shifted from "expansion" to "technological leapfrogging", with high voltage, lightweight, and intelligence becoming the three main themes.

Market Size: New Energy Accounts for 60%, with Doubled Value per Vehicle. By 2025, the wire harness market is expected to reach 120 billion yuan, with new energy wire harnesses accounting for over 60% for the first time. The wire harness for a fuel vehicle costs about 3,000 yuan per vehicle, while that for a new energy vehicle generally exceeds 5,000 yuan, and for high-end smart models, it can exceed 8,000 yuan. Incremental components such as LiDAR and domain controllers have increased both complexity and value density.

"Three arrows of technology"

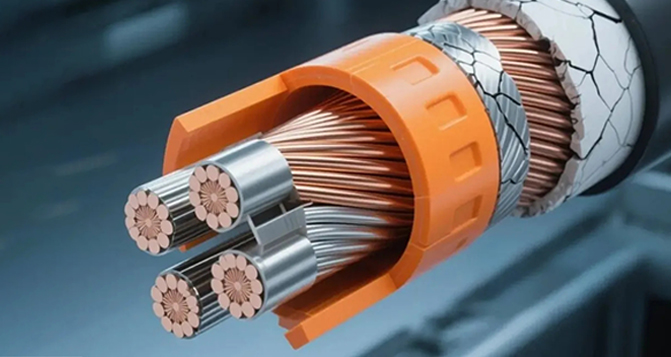

High-Voltage: 800V platform on the vehicle, withstand voltage increased to 1500V+; silicone insulation at 200℃, three-layer shielding, liquid-cooled wiring harness, ensuring stability even during supercharging.

Lightweight: Replacing copper with aluminum, reducing weight by 30%. Nano-coated aluminum wire prevents oxidation, thin wall + carbon fiber sheath reduces overall vehicle weight by 60%, and increases range by 5-10%.

Intelligentization: Harnesses become "data hubs" with on-board Ethernet at 10Gbps and fiber demand increasing by 62% annually, while AI-based automatic wiring shortens development cycles by 40%.

Pattern: Domestic substitution in deep waters. 71% of the global market share is still held by Japanese, German, and American giants (Yazaki, Sumitomo, Aptiv), while local players have seized 28% with high-voltage aluminum bundles, modularization, and fast response. Huguang, Tianhai, and Zhonglian have entered the supply chains of BYD, NIO, and Tesla, but high-end connectors and high-speed data cables still rely on imports.

Challenges: Cost, recycling, high copper prices in overseas markets → futures hedging + substituting aluminum for copper; EU's new regulation requires a recycling rate of ≥95%, forcing a closed-loop system; building factories in Mexico and Hungary to bypass trade barriers.

Outlook: From 2026 to 2031, we will move towards "seamless wiring" with wireless UWB and Bluetooth LE, reducing wire length by 50%; utilizing bio-based sheaths to reduce carbon emissions; and implementing digital twin factories to boost yield to 99.9%.

"Wiring harnesses are no longer mere wires, but intelligent components that participate in energy and data decision-making." - Head Tier 1 Technology Director 2026. The wiring harness industry stands at the crossroads of a "neural revolution". Only those who make breakthroughs in materials, intelligent manufacturing, and global collaboration will be able to seize the next five years.

Special statement: The content is sourced from Harness World for reference only, aiming to disseminate more information rather than for profit. The copyright belongs to the original author. If there is any infringement, please contact us for removal.