As a key actuator for fluid control, solenoid valves play an extremely important role and are indispensable in the braking and suspension systems of new energy vehicles due to their advantages of fast response, high-precision control, and reliability.

1. Application of solenoid valves in braking systems

1.1 Braking force distribution and Anti lock Braking System (ABS)

The braking system of new energy vehicles needs to coordinate traditional friction braking and energy recovery braking. The solenoid valve achieves dynamic distribution of braking force among the four wheels by precisely controlling the brake fluid pressure during this process.

In the ABS system, the solenoid valve adopts a high-speed switching valve (two position two-way valve), which controls the duty cycle through high-frequency PWM (pulse width modulation) to increase, maintain, and decrease the brake pressure. For example, a normally open solenoid valve allows brake fluid to flow to increase pressure, while a normally closed solenoid valve blocks flow to maintain pressure stability.

In the hEMB system (hybrid scheme), the front wheels are driven by EMB motors, while the rear wheels retain hydraulic braking. The front and rear braking force distribution and fault switching are achieved through solenoid valves. When an electrical failure occurs, the solenoid valve opens and the driver's pedal force acts directly on the rear wheel caliper through the hydraulic path.

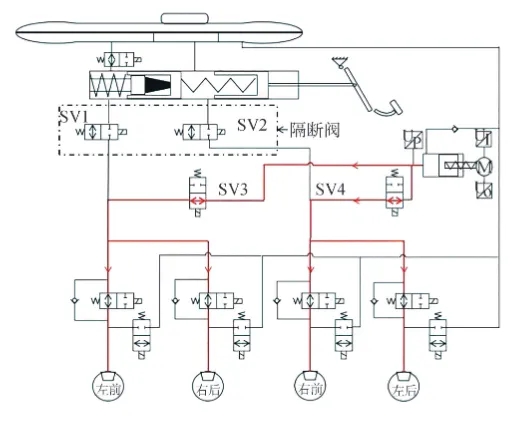

As shown in the figure, the two isolation solenoid valves SV1 and SV2 achieve decoupling between the pedal simulator and the wheel cylinder hydraulic circuits. A braking system that can achieve driver pedal decoupling, in addition to an integrated electro-hydraulic braking system, can also use electronic pedals, electronic control units, and wheel end control modules (motors) in electronic mechanical braking EMB systems, electromagnetic braking systems, etc., to achieve decoupling between the driver and the brake caliper.

1.2 Energy Recovery and Braking Coordination

In energy recovery braking, the solenoid valve needs to work in conjunction with the vehicle control unit (VCU). When the driver lightly steps on the brake pedal, the solenoid valve prioritizes the energy recovery mode, reducing the intervention of mechanical braking by adjusting the hydraulic system pressure, and converting kinetic energy into electrical energy storage. During emergency braking or when the battery is fully charged, the solenoid valve quickly switches to traditional friction braking mode to ensure safety. For example, the Bosch iBooster system achieves electro-hydraulic coupling through solenoid valves, reducing reliance on vacuum assistance.

2. Application of solenoid valves in suspension systems

2.1 Height and stiffness adjustment of air suspension

High end new energy vehicle models (such as the U7) adopt active air suspension, and the solenoid valve plays the core function of gas flow control in this system.

Height adjustment: Control the flow of compressed air into the airbag through an electromagnetic valve to achieve vehicle lifting or lowering. For example, lowering the body to reduce wind resistance while driving at high speeds, and lifting the chassis to increase off-road capability.

Stiffness adjustment: The solenoid valve combines sensor signals to dynamically adjust the air pressure inside the airbag and change the suspension damping characteristics. For example, the Yunnian-Z system can complete stiffness adjustment within 10ms through algorithm iteration, achieving smoothness without jumping over obstacles.

2.2 Active Damping Control (CDC)

In electromagnetic suspension systems, such as the Tesla Model S Plaid, solenoid valves adjust the hydraulic oil flow to change the damping force of shock absorbers. When a bumpy road surface is detected, the solenoid valve increases the cross-sectional area of the oil flow and reduces the damping force to improve comfort; When turning at high speed, the solenoid valve reduces the flow area and increases damping force to suppress roll.

Special statement: The content is sourced from Huaruoting Cloud and is intended for reference only, to convey more information and not for profit. Copyright belongs to the original author. If there is any infringement, please contact us for deletion.